porthole

Retired

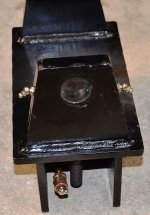

Here are the results of just over a year of ownership and 6166 miles of trailer towing (yes I do keep track), with proper maintenance of a $2600 plus hitch.

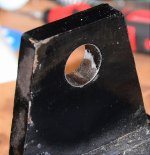

1st picture is of the jaw pins.

They have never had any lube - from the day of assembly!

They were bone dry when removed. Good thing there is little movement and you are using the truck to move the jaws around the pin box pin.

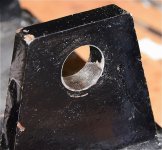

The next 3 pictures are the saddle pins. They had some fresh assembly grease on the inner, outside faces of the pins, what was left from the original installation pushing through.

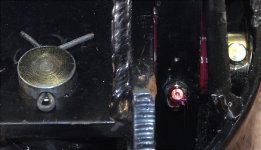

They had, for the most part a bit of dried up grease around the pin. As you can plainly see, this is a metal to metal friction fit and not wearing well at all. You can just see what was left of this grease in the 5th picture (yellow arrow).

1st picture is of the jaw pins.

They have never had any lube - from the day of assembly!

They were bone dry when removed. Good thing there is little movement and you are using the truck to move the jaws around the pin box pin.

The next 3 pictures are the saddle pins. They had some fresh assembly grease on the inner, outside faces of the pins, what was left from the original installation pushing through.

They had, for the most part a bit of dried up grease around the pin. As you can plainly see, this is a metal to metal friction fit and not wearing well at all. You can just see what was left of this grease in the 5th picture (yellow arrow).