- Home

- Forums

- HEARTLAND RVs GENERAL AREA

- Exterior Components - For all Heartland brands

- Axles, Brakes and Suspension

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wheel bearing lubrication

- Thread starter cruzin101

- Start date

mlpeloquin

Well-known member

Grease fitting should not be on fifth wheels. Dittos for doing it the correct way. Great for Boat trailers that take a dip in the water though.

They should delete this feature for the RV axles. Both of my fifth wheels came from the dealer, with the brakes full of grease. I dont think the factory pumped them full, I believe it was the dealers service guys. There is no way to see how much grease your putting in thru those zerks. Nor can you tell where it is actually going.

Instead of oozing toward the front outer bearing, most often the grease blows by the rear seal, and into you brakes. And then you have to replace everything, cause the brakes shoes once greased can NOT be wiped off and used again they need to be replaced.

Instead of oozing toward the front outer bearing, most often the grease blows by the rear seal, and into you brakes. And then you have to replace everything, cause the brakes shoes once greased can NOT be wiped off and used again they need to be replaced.

jerryjay11

Well-known member

I've used zerk fittings on several camper and boat trailers and never blew the seal out. The key is to lift the wheel off the ground so you can rotate it at the same time you are hand pumping. Do not rush it, just stroke the handle one pump at a time, giving time for the grease to enter, while rotating the wheel. When full it will appear at the outside of the outer bearing. Periodically I will remove the bearings to inspect the spindle, bearings, races, etc. The problem comes when a shop uses a pressurized grease system or attempt to pump the handle repeatedly to force feed the bearings, thus building up pressure within the hub.

avvidclif

Well-known member

I use a grandson to spin the wheel while I slowly apply grease until it comes out. The first time it must have been empty as it took a bunch but it finally did. A bunch was not enough to fill the area the brake shoes are in either. Dexter has instruction on how to properly do it.

Now explain why I need to pack the bearings every year? I packed the front wheel bearings on my old PU abt 20 years and 120k miles ago and they are still fine.

Now explain why I need to pack the bearings every year? I packed the front wheel bearings on my old PU abt 20 years and 120k miles ago and they are still fine.

NYSUPstater

Well-known member

Not meaning to hijack this thread, but a question for my buddy who is doing a complete re-pack/bearing job to his TH.

He is going to take things apart next week and replace all the bearings and seals and pack 'em w/ grease. Question he asked me to which I did not have an answer for is: Does he need to put grease into the zerks on the axles if he greases up the bearings well before installing them? I have no clue where the holes in the axles are for the grease to come out and where/what exactly does the grease go from the zerks?

Told him I'd check and get back to him. Personally, like a couple others above, all I've ever done is just spin the tires and pump 3-4 shots of grease in. Knock on wood, no problems. Every couple of years I would have dealer check a wheel just to make sure things looked good and greased, then say every 3-4 years, have them take apart and re-do things. May not be the best way, but has worked for me and dealer has done okay by me.

He is going to take things apart next week and replace all the bearings and seals and pack 'em w/ grease. Question he asked me to which I did not have an answer for is: Does he need to put grease into the zerks on the axles if he greases up the bearings well before installing them? I have no clue where the holes in the axles are for the grease to come out and where/what exactly does the grease go from the zerks?

Told him I'd check and get back to him. Personally, like a couple others above, all I've ever done is just spin the tires and pump 3-4 shots of grease in. Knock on wood, no problems. Every couple of years I would have dealer check a wheel just to make sure things looked good and greased, then say every 3-4 years, have them take apart and re-do things. May not be the best way, but has worked for me and dealer has done okay by me.

DirtyMax88

Well-known member

You shouldn't need the axle fittings If you hand pack. I never use them, you have to fill the hubs full of grease before any gets to the outside bearing. I grease mine about every 4 years

Sent from my SM-G950U using Tapatalk

How many miles do you travel a year? Every 4 years seems like a long time in between? I believe MoRryde recommended that we get it done every 2 years or 12k miles....

Silverado23

Iowa Chapter Leaders

You shouldn't need the axle fittings If you hand pack. I never use them, you have to fill the hubs full of grease before any gets to the outside bearing. I grease mine about every 4 years

Sent from my SM-G950U using Tapatalk

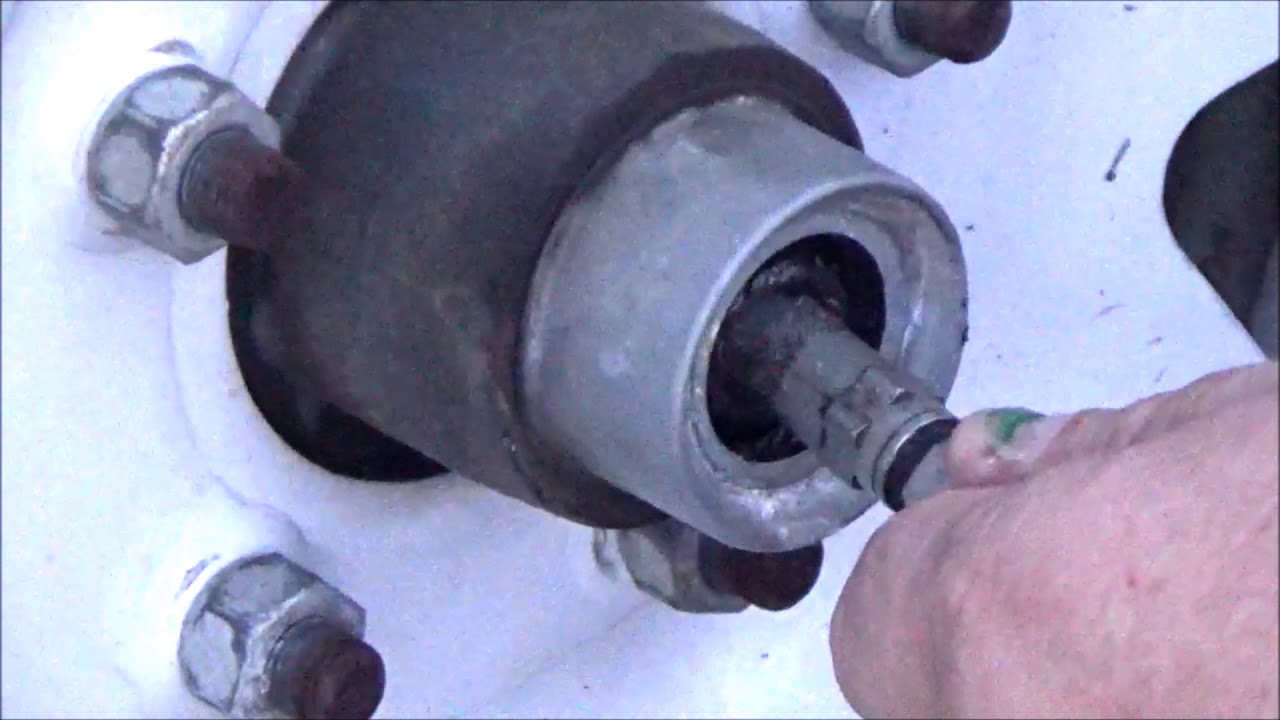

The ez lube hub is not the same as a bearing buddy that snaps on to the hub and is confusing to those that don't know how the ez lube hub by dexter work.

The ez lube hubs do not use as much grease as you may think

Here is a video that shows how they work.

https://www.dexteraxle.com/resources/videos/e-z-lube-system

danemayer

Well-known member

If it has a zerk fitting in the center of the hub, it's an EZ lube.I would like to know how to see if my 2015 Cyclone 3110 has Dexter EZ lube hubs?

Daley07

Active Member

The best RV wheel-bearing grease that I found is Plews & Edelmann LMX. It is really convenient and easy to use. It is soft enough to be applied to bearings. It does not drip easily, so it will linger where it has been applied. In addition, this grease has anti-corrosion properties that help prevent the gradual deterioration of my bearings. This is very convenient because I won't have to think about getting a replacement soon. This grease is insoluble in water, so there are times when my RV wheels are wet due to road conditions during the rainy and winter seasons. I’m always confident that the bearings are well lubricated.

Last edited:

stretchb1953

Member

I have a wilderness with ez lube fittings on it. my question is if i have only taken 1 trip of about 2200 miles, in 2 years, do i need to go ahead and hand pack or am i good with just shooting my hubs with grease for another trip? also, how do you remove the bearings with an ez grease sert installation?

MTPockets

Well-known member

My entire 49 year career, smong other things, incuded training factory maintenance people about lubricants and proper lubrication practices; For bearings.... the biggest feedback I got, repeatedly, was that too many maintenance people seemed to refuse actual, proper bearing maintenance techniques. They usually kept doing what they always 'believed' - pump lots of grease and do it often ..... those customers spent a lot more maintenance budget on grease and replacing bearings than those who would listen.... without taking hours to explain why ... for trailer wheels, throw away the EZ lube, grease guns, expensive greases, and filling up the whole wheel cavity with grease. It's a waste of grease and does nothing. Just use a brand name lithium based grease, (don't mix grease types) hand pack the bearing, and drive. Or, do it your way and gain nothing.

I use a Shell product called Gadus V220 S3 for my bearings.I”ve never had an issue with bearings. It doesn’t melt under heat, lithium based,does not dissolve in water ETC. And I do concur with MTPockets comment....do not mix greases,

Not all greases are compatible with each other...product bases are different and different ingredients are used.I worked 35 years in lubes for Shell so learned a lot about oil/ grease properties.

Not all greases are compatible with each other...product bases are different and different ingredients are used.I worked 35 years in lubes for Shell so learned a lot about oil/ grease properties.

stretchb1953

Member

I see a lot of owners praise lithium grease. what is wrong with the regular old wheel bearing grease i have used for years on my vehicles? I use a Moly EP type grease

MTPockets

Well-known member

Nothing wrong with it... its most likely still Lithium based grease with molybdenum additive (moly), which is a solid material. Molybdenum by itself would look like black talcum powder, so it needs a carrier/base; i.e. most commonly lithium.I see a lot of owners praise lithium grease. what is wrong with the regular old wheel bearing grease i have used for years on my vehicles? I use a Moly EP type grease

MTPockets

Well-known member

More FYI..... (copied from lube engineering)Nothing wrong with it... its most likely still Lithium based grease with molybdenum additive (moly), which is a solid material. Molybdenum by itself would look like black talcum powder, so it needs a carrier/base; i.e. most commonly lithium.

Grease can be thought of in terms of paint in that there are a variety of formulations that are used in various applications. You could apply latex paint to the hull of your boat and it would look very nice, however, it would not last very long once your ship went to sea, and vice versa. The paint that you would use for your boat, although quite effective, would not look very good when applied to the walls of your home. Moly grease is a special formulation that is used in situations where metal slides against mental under high pressure and is generally used on pinion gears and splines.

This silvery black solid compound, which naturally occurs as the mineral molybdenite, is classified as a metal dichalcogenide. The compound is not affected by oxygen or dilute acids. It looks and feels similar to graphite. Because it is so robust and features low friction properties, it is often used as a solid lubricant.

Sliding surfaces, such as axles, require different types of grease and black moly grease is used whenever the services in question are under great pressure. In most cases, you will use whatever type of grease is called for in the service manual. For anything that requires grease, there will be a symbol that resembles a grease gun and has one of the following:

GREASE - Multi-purpose, grease that is lithium-based

- M - (MOLY GREASE) Molybdenum disulfide grease; moly content to be at least 3%

- MP - (MOLY PASTE) Molybdenum disulfide paste; moly content to be at least 40%

- S - Silicone grease

How Moly Grease Works

Several different molecules make up the hexagonal crystal platelets of moly. There is one molybdenum atom and two sulfur atoms in each molecule of moly. What makes moly platelets special is their affinity to metal surfaces. The combination of this affinity, especially when considering how moving parts, when sliding around, can cause the thermochemical reaction that is required for moly to provide its armor-like overlapping coating of protection to engine parts.

Moly platelets have the characteristic of being able to slide across engine surfaces quite easily. This allows metal to rub against metal while being protected by the lubricating properties of moly grease.

Generally speaking, if the service manual calls for moly grease than that is what you need to use. It is recommended for shock loading and bearings that are subject to especially heavy loads such as those that are found in CV joints and universal joints. Conversely, problems can be experienced if this type of grease is ever used in parts such as high-speed bearings.

Similar threads

- Replies

- 1

- Views

- 159

D

- Replies

- 5

- Views

- 638