Roadpossum

Member

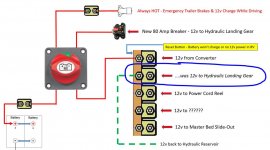

2016 Bighorn 3270RS

I keep getting a Low Battery message on my Lippert Levelup display. I am also having intermittent shutdowns during operation of the levelers. I have four L16 AGM batteries and my solar display, as well as my inverter display both show a 13.4VDC battery voltage, while the Levelup display shows 12.1VDC. I'm assuming I have a loose connection somewhere or a bad breaker that is causing the voltage drop. Is there a wiring diagram available that will tell me what breaker is used for what circuit? Thanks for any input or suggestions... Curt

I keep getting a Low Battery message on my Lippert Levelup display. I am also having intermittent shutdowns during operation of the levelers. I have four L16 AGM batteries and my solar display, as well as my inverter display both show a 13.4VDC battery voltage, while the Levelup display shows 12.1VDC. I'm assuming I have a loose connection somewhere or a bad breaker that is causing the voltage drop. Is there a wiring diagram available that will tell me what breaker is used for what circuit? Thanks for any input or suggestions... Curt