My comments assume you have the EZ-Lube system. If you repack on an annual basis or 10,000 miles whichever is first, you cannot go wrong. But here is my 2 cents.

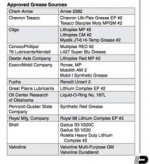

The Timken grease is great grease, but you need to buy it in a tube so you can not only repack by hand, but also add grease with a grease gun. Page 13 from this Dexter owners guide will give you the grease acceptable to Dexter Axle. Is the Timken grease you are looking at listed there?

http://www.dexteraxle.com/i/u/6149609/f/Service_Resources/Bearing_Lubrication_Chart.pdf

View attachment 34805

Until you repack your bearings it is imperative that you use a grease from the list as the "soap bases" must be compatible with the grease dexter used originally. These greases are compatible.

$4 per tube or less is a fair price for wheel bearing grease. Over that you are paying for marketing hype. There is no magic in one brand versus another. It might make you "feel good" to buy expensive grease, but expensive is not better. You should be able to buy 10 14 oz tubes of quality wheel bearing grease for about 36 bucks. That is a lifetime supply.

I bought 10 tubes of Conoco Multiplex Red for 36 bucks off the internet and did not pay sales tax or freight.

If you have EZ lube you will want this grease gun

http://www.amazon.com/Alemite-555-E-Develops-Cartridge-Extension/dp/B009K530KS

Dexter recommends repacking every 10,000 miles or 12 months whichever is first. Other guys can do that but I'm not. I will lube with the ez-lube and I will inspect the brakes as required, during the brake check I will examine the seals and bearings, if I detect problems I will R&R every axle and bearing. Until then, I'm shooting a couple of squirts in the EZ-Lube zerk and enjoying my rig.

Skip the annual hand pack and all the time and expense and put the money into tires, you will get a better return on investment.