You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

It's here!!Mixed feelings...

- Thread starter SouthernNights

- Start date

-

- Tags

- it's

SouthernNights

Past South Carolina Chapter Leader

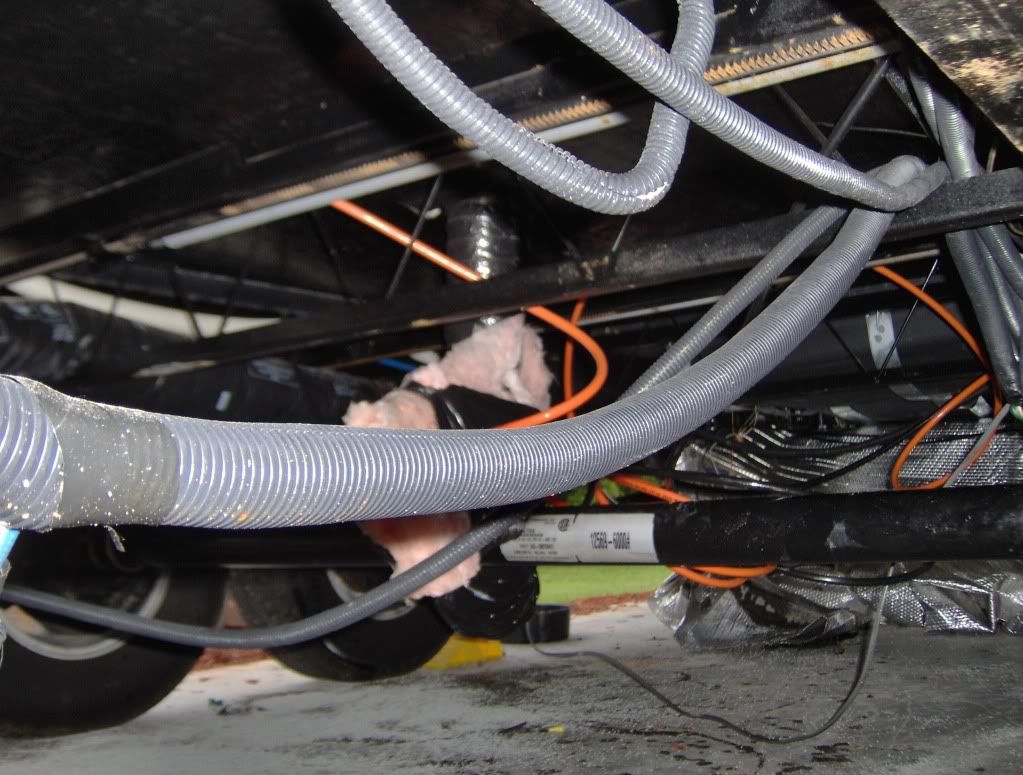

WOW - Hope mine doesn't look that bad!!!

I don't think this is much different than any other trailer.There have been a couple of posts here of people dropping their belly pan and cleaning up the systems. Their "before" pictures look similar to this.

From an engineering stand point, it's not too bad. The only real problem I see is the routing of the duct work. The teeth on the slide is cutting into the duct work.

From a workmanship standpoint, wow-really poor.

What surprises me is the amount of waste that is allowed to go on. I cleaned up the wires behind my electric panel inside the coach and all the wires and duct work in the basement.

I had about 6 feet of duct work left over from just two ducts and I dont know how many feet (alot) of wire.

Maybe there is a reason for all the excess, but I cant for the life of me figure out what it is. Even allowing for flex and vibration, it just doesnt make sense.

.

Bob and Gary,

Thank you so much for bringing this to light. We see this same complaint/comment so many times here but few realize how it translates to dollars. The same dollars most of us are watching so closely these days. If people want neat-and-tidey wiring and plumbing then they better be ready to pay for it.

Thank you,

Mark

When I purchased my unit, I PAID FOR NEAT & TIDY!

Eh!

DMitch

Well-known member

I currently own a Select Suite by Double Tree, it is suposed to be a top of the line unit. I can tell you it has the same kind of wiring and plumbing mess behind the walls and under the belly pan. I currently have a BH 3580 on order and was hoping that based on the fit and finish of the inside that I would not have this mess in the new one. I don't think there is any excuse for this type of wormanship, if my unit comes in this bad I am not going to be happy. What is the logical reason for any production worker to cut a whole in a wall like we have seen here? It's prob. quicker to drill a neat hole that beat one out of the wall with a hammer, which is what this looks like. Don't intend to rip Heartland apart with my comments, I think the Big Horn is the best bang for the buck on the market, but accoring to these pictures quality control needs some attention.

Uncle Rog

Well-known member

Tool Chest and Fuses..............

The horn is our fourth RV and is hands down the nicest we have owned.

Have we had a few issues? Yes we have.

However, none of them would have been deal breakers for us, the unit is that nice.

The previous units were no where near as complex as the horn as far as operating systems and features, and we still had issues with them also.

We are planning a few trips this summer and into the fall, and since this is our third season I am going to open up the basement and check out all the connections, fittings, valves and duct work, regular preventative maintenance care.

I think all in all this is the best made unit we have had. notwithstanding a few bumps in the road, what.

My feeling is if you are going to own an RV and you don't have a tool box and a bag full of fuses your best bet would be to make reservtions somewhere instead.

I have also been planning to build a couple of recessed shelves into the bulkhead panels, for quick access stuff.

The horn is our fourth RV and is hands down the nicest we have owned.

Have we had a few issues? Yes we have.

However, none of them would have been deal breakers for us, the unit is that nice.

The previous units were no where near as complex as the horn as far as operating systems and features, and we still had issues with them also.

We are planning a few trips this summer and into the fall, and since this is our third season I am going to open up the basement and check out all the connections, fittings, valves and duct work, regular preventative maintenance care.

I think all in all this is the best made unit we have had. notwithstanding a few bumps in the road, what.

My feeling is if you are going to own an RV and you don't have a tool box and a bag full of fuses your best bet would be to make reservtions somewhere instead.

I have also been planning to build a couple of recessed shelves into the bulkhead panels, for quick access stuff.

SouthernNights

Past South Carolina Chapter Leader

The horn is our fourth RV and is hands down the nicest we have owned.

Have we had a few issues? Yes we have.

However, none of them would have been deal breakers for us, the unit is that nice.

The previous units were no where near as complex as the horn as far as operating systems and features, and we still had issues with them also.

We are planning a few trips this summer and into the fall, and since this is our third season I am going to open up the basement and check out all the connections, fittings, valves and duct work, regular preventative maintenance care.

I think all in all this is the best made unit we have had. notwithstanding a few bumps in the road, what.

My feeling is if you are going to own an RV and you don't have a tool box and a bag full of fuses your best bet would be to make reservtions somewhere instead.

I have also been planning to build a couple of recessed shelves into the bulkhead panels, for quick access stuff.

Uncle Rog,

Not sure what you are driving at. My issue is not with preventitive maintenace.

Uncle Rog

Well-known member

I guess I did ramble on a bit.

I have had to clean up basically the same stuff in every unit we have owned.

Since everything works I basically put off messing with it until I had to go in and check things out.

I just accept that every RV is going to need some clean up work to get it the way I want it.

No excuses for HL or any other manufacturer.

This is not the America I grew up in and I have resigned myself to expect less from "Made in the USA".

I have had to clean up basically the same stuff in every unit we have owned.

Since everything works I basically put off messing with it until I had to go in and check things out.

I just accept that every RV is going to need some clean up work to get it the way I want it.

No excuses for HL or any other manufacturer.

This is not the America I grew up in and I have resigned myself to expect less from "Made in the USA".

SouthernNights

Past South Carolina Chapter Leader

Roger,

It is a shame, but you are right. Made in America has changed but it is still better than second best.

I should have read between your lines.

I am not trying to be overly critical of HL. It is by far the prettiest trailer I have ever owned. The floor plan of the 3250 shows very progressive thinking.

But pretty should be more than skin, or interior, deep.

And pretty does not have to cost alot. It took me less than 4 hours to make a new panel, add a seperate ground bar with redundant grounds, add a seprate wire terminal block,(both to get rid of wire nuts that fall off), reroute wires in the basement and reroute the ducts so they are straighter. Think about how fast it could have been when the coach was built. I spent most of my time taking it apart.

I do not know how many coaches HL builds a year. But if they could save 5 dollars per coach by not wasting so much wire, ducting and hydraulic hose, and build 1000 units per year, thats 5k to the bottom line per year.

Why wouldn't you do that???????? That is free money, AND cleans up the coach a little AND makes a better impression on workmanship. Even in a company with 7 digit sales, any CFO would get a smile at a 5k plus with no up front cost.

Do you remember the cars of the 80's? Open the hood and what a mess of hoses and wiring. Perceived quality, or lack of it, helped the Japan automakers get a solid foot hold in this country.

With all the research we did on trailers, finding HL, and seeing what this company stands for and what it has done for the market, I would hate to see the company not succeed due to a few employees who do not take pride in their work.

It is a shame, but you are right. Made in America has changed but it is still better than second best.

I should have read between your lines.

I am not trying to be overly critical of HL. It is by far the prettiest trailer I have ever owned. The floor plan of the 3250 shows very progressive thinking.

But pretty should be more than skin, or interior, deep.

And pretty does not have to cost alot. It took me less than 4 hours to make a new panel, add a seperate ground bar with redundant grounds, add a seprate wire terminal block,(both to get rid of wire nuts that fall off), reroute wires in the basement and reroute the ducts so they are straighter. Think about how fast it could have been when the coach was built. I spent most of my time taking it apart.

I do not know how many coaches HL builds a year. But if they could save 5 dollars per coach by not wasting so much wire, ducting and hydraulic hose, and build 1000 units per year, thats 5k to the bottom line per year.

Why wouldn't you do that???????? That is free money, AND cleans up the coach a little AND makes a better impression on workmanship. Even in a company with 7 digit sales, any CFO would get a smile at a 5k plus with no up front cost.

Do you remember the cars of the 80's? Open the hood and what a mess of hoses and wiring. Perceived quality, or lack of it, helped the Japan automakers get a solid foot hold in this country.

With all the research we did on trailers, finding HL, and seeing what this company stands for and what it has done for the market, I would hate to see the company not succeed due to a few employees who do not take pride in their work.

jmgratz

Original Owners Club Member

Hey guys, why not make your suggestions directly to Heartland, they listen and in many instances make the suggested changes. If your suggestions can save them money without any "out of pocket" expenses you will definitely have 'their ear'. Part of the reason for 'the mess' is time constraints. 4 hours to clean up a mess of wires could translate into completing 6-8 units. I asked one of the worker repairing our coach here at the Heartland Rally about where all the extra screws come from and he told me when they are on the production line and drop a screw it is quicker and easier to grab another rather than stop, find and pick up the dropped one. The bottom line is time. Now if there was a group on the assembly line making a wiring harness it could be done neater. I do agree though that the 'bird's nest' is unsightly.

Last edited:

Uncle Rog

Well-known member

jm, point well made again. I think one issue is the speed in which HL makes changes to each model over a fairly short period of time. I ran into a 3670rl at a CG close to me late in '06, the hook ups and UDC were completely different than mine and it was only built a couple of months prior. Our esteemed mentor Forrest has the same unit built around the same time as ours and from his pictures there are variances in his unit also. I guess the point is if HL is going to standardize a plan the mass production principles could be applied and efficiency would be improved.

I have a friend, much more sage in his RV experience then I, has a Lazy Daze MH that is 14 yrs old and is pretty much bullet proof. That being said they have not changed much of anything in their units since '92, save for the chassis and a little cabinet work. That has given them 16+ years to get it right.....................

One last thought, he sure likes the horn!

I have a friend, much more sage in his RV experience then I, has a Lazy Daze MH that is 14 yrs old and is pretty much bullet proof. That being said they have not changed much of anything in their units since '92, save for the chassis and a little cabinet work. That has given them 16+ years to get it right.....................

One last thought, he sure likes the horn!

SouthernNights

Past South Carolina Chapter Leader

Jim,

The factory does follow these posts. The prod. mgr., Bryan has posted on this thread.

The factory does follow these posts. The prod. mgr., Bryan has posted on this thread.

porthole

Retired

I skipped through the last four pages so hopefully this is not redundant.

First time I saw a picture like the one from the beginning of this thread I made it a point to look in those areas of trailers I was interested in.

If the workmanship is poor in the easily accessible areas imagine in the areas you can't see!

I got to see just about every step of Cyclone production, from bare chassis to completed product during my recent visit, especially the new 3010 which I recently ordered.

Nowhere did I see anything like the rats nest pictured. Had I seen anything like that the Cyclone would have been scratched from my list.

My first career was that of an auto tech (mostly Chrysler corp dealers).

My early mentors instilled in me the notion that "there is never enough time to do it right the first time - but there is always enough time to do it right the second time".

That quote does not refer to the factory screwing it up and then me fixing it but rather when I did work on a vehicle I took the time to do the work correctly the first time.

First time I saw a picture like the one from the beginning of this thread I made it a point to look in those areas of trailers I was interested in.

If the workmanship is poor in the easily accessible areas imagine in the areas you can't see!

I got to see just about every step of Cyclone production, from bare chassis to completed product during my recent visit, especially the new 3010 which I recently ordered.

Nowhere did I see anything like the rats nest pictured. Had I seen anything like that the Cyclone would have been scratched from my list.

My first career was that of an auto tech (mostly Chrysler corp dealers).

My early mentors instilled in me the notion that "there is never enough time to do it right the first time - but there is always enough time to do it right the second time".

That quote does not refer to the factory screwing it up and then me fixing it but rather when I did work on a vehicle I took the time to do the work correctly the first time.

Last edited:

I bought a Big Country 3355 a couple of weeks ago. Took it out on our first campout this week. On the second day I noticed a water leaking under the stairs. Called Katy, Tx camping world and they told me to look for a few things. I was only about 1 hour away from the Camping World that I purchased the 5th wheel. I asked if they could send someone to repair it. They said they were too busy. So I asked if I brought it in since we were out camping if they could look at it right away so I could get back to the rv park. The said it would take at least three days before they could get to it.

So I called an rv repair service. Hopefully I will be reimbursed. They found three water line leaking at the connections. These leak was coming out of the fraime onto the ground. But the main leak in the inside of the rv was coming from the sewer line. They had to replace the line for a permanent repair. Apparantly Heartland needs a lot better quality control.

Jaime

So I called an rv repair service. Hopefully I will be reimbursed. They found three water line leaking at the connections. These leak was coming out of the fraime onto the ground. But the main leak in the inside of the rv was coming from the sewer line. They had to replace the line for a permanent repair. Apparantly Heartland needs a lot better quality control.

Jaime

out the car window

Member

we have a different model BC - but hope this can help someone ......

Hi

We have the same mess of wired and hoses in our BC. One thing we found is that we could not get heat to the rear of the unit. Dealer wanted to fit fans and all manner of 'stuff'. In the end I pulled off the covers and looked - the main hose to the living area and beyond was completely flat as it left the furnace (jammed into the support) - whereas the one to the bedroom toilet was positioned to get max heat. So we froze in the living area and ...well no need for details. If you take the cover off to take a look at this - check the hoses of the furnace and see if they need to be switched, shortened or straightened. We have a good heat flow now.... but only when I found the problem and told them what they had to do to fix it.... I am no expert but maybe worth a look....

le

Hi

We have the same mess of wired and hoses in our BC. One thing we found is that we could not get heat to the rear of the unit. Dealer wanted to fit fans and all manner of 'stuff'. In the end I pulled off the covers and looked - the main hose to the living area and beyond was completely flat as it left the furnace (jammed into the support) - whereas the one to the bedroom toilet was positioned to get max heat. So we froze in the living area and ...well no need for details. If you take the cover off to take a look at this - check the hoses of the furnace and see if they need to be switched, shortened or straightened. We have a good heat flow now.... but only when I found the problem and told them what they had to do to fix it.... I am no expert but maybe worth a look....

le

sdgrossman1994

Member

More of the same....

Hello to all. I just finished reading this entire thread to see what the common problems that everyone is having with their units when they are new. I just purchased a brand new 2009 Big Country 3490 RB. Now...I know that the 2011's are hitting the street but the price was right, and this floorplan is just what we wanted in the price range we were shopping in.

We are full-timing in our BC and it is just like anything else, embedded with it's own problems. Here are the problems that I have discovered so far.

1. Two broken water fittings on the winterizing valve that soaked the basement . Lucky for me...I discovered it before I put anything in there, so it was just wet carpet. I repaired them myself as I cannot see taking it to the dealer since I am full-timing in it for just a simple repair.

. Lucky for me...I discovered it before I put anything in there, so it was just wet carpet. I repaired them myself as I cannot see taking it to the dealer since I am full-timing in it for just a simple repair.

2. Gray 1 and 2 tanks drain extremely slow. It's been in the 20's and 30's so I have not been able to look into this issue. Hopefully it's not going to have something in there restricting it from flowing.

3. The satellite wiring to the forward bedroom does not work . It will not allow a receiver to get a signal. I have not looked into this yet, but I am sure since it's right above the basement that it will be easy to troubleshoot and repair.

. It will not allow a receiver to get a signal. I have not looked into this yet, but I am sure since it's right above the basement that it will be easy to troubleshoot and repair.

4. The area behind the wall in the basement is a mess. There is sawdust and wood shavings, numerous pieces of wiring insulation and wiring pieces from when they stripped the wire ends to install something, and there is no organization in the wiring or plumbing at all (I will fix that

(I will fix that  ).

).

5. The outside speakers are very distorted like they are blown. I don't know for sure yet, because I have not looked into it, and it's in the 30's outside, but from what I can hear, it must have been played loud while on the RV lot and by mistake blown. I will have to look at it and determine what I am going to do about it.

From a Quality Assurance (QA) standpoint, if you are going to streamline a process for efficency and increased quality (cost wise readiness), then it's got to start and be accepted by all members of the process. If HL is going to build a trailer, and they do build a nice unit , then the QA process must mandate that they route the wiring and plumbing in such a way as to make it as neat and professional during the initial installation to prevent problems from occurring later as a result of this sloppy install.

, then the QA process must mandate that they route the wiring and plumbing in such a way as to make it as neat and professional during the initial installation to prevent problems from occurring later as a result of this sloppy install.

There is no additional cost associated with installing the wiring into a preplanned correct location or area that would allow for a neater and more professional installation. The technician is already in there doing the work, so what additional cost is associated with just putting in the right way for the first and only time? NONE. This is not a cost factor, it's a fact of not having a process in place that would foster a better install. It's been overlooked and accepted as "This is the way we have always done it" attitude that will keep them installing this way. This can change and I'm sure with the brand manager looking at these forums, that changes will come that will eliminate the sloppy intallations in the future.

There was someone that said he was not going to mess with it because if "It's not broke...don't mess with it" was his response. Well...in retort to that statement...I don't want to be setting up in the middle of the moutains ready for a wonderful RV'ing experience with my family when something is broken from the trip up there and have to listen to my wife complain that it's broken and that I should have checked it. So prevention is the key to success.

The Pre-Delivery Inspection (PDI) should be thorough as it can be. Hook it all up and check it all out with the dealer right there. If they don't make time for you, then demand it. Experienced or not, it's their job to deliver a unit to you that you are happy with. I did not take the time that I wanted to because I was on a schedule to get back home at a certain time. I live four hours from my dealer, so I assumed the risk associated with what I would discover once I set it up. I can repair most anything so I'm not affraid to repair the RV.

Please understand that I don't defend sloppy work, but at the time same time, if it's not part of the process to install it in a way that is neat and professional looking, then it won't change. Our input and feedback to HL is what is going to change the future RV's for the next potential HL owner.

I am enjoying my Big Country and look forward to many years of use out of my RV.

My two cents....

Scott

2009 Big Country 3490 RB

2005 Ford F-350 Lariet 6.0L Powerstroke DRW Crewcab

Hello to all. I just finished reading this entire thread to see what the common problems that everyone is having with their units when they are new. I just purchased a brand new 2009 Big Country 3490 RB. Now...I know that the 2011's are hitting the street but the price was right, and this floorplan is just what we wanted in the price range we were shopping in.

We are full-timing in our BC and it is just like anything else, embedded with it's own problems. Here are the problems that I have discovered so far.

1. Two broken water fittings on the winterizing valve that soaked the basement

2. Gray 1 and 2 tanks drain extremely slow. It's been in the 20's and 30's so I have not been able to look into this issue. Hopefully it's not going to have something in there restricting it from flowing.

3. The satellite wiring to the forward bedroom does not work

4. The area behind the wall in the basement is a mess. There is sawdust and wood shavings, numerous pieces of wiring insulation and wiring pieces from when they stripped the wire ends to install something, and there is no organization in the wiring or plumbing at all

5. The outside speakers are very distorted like they are blown. I don't know for sure yet, because I have not looked into it, and it's in the 30's outside, but from what I can hear, it must have been played loud while on the RV lot and by mistake blown. I will have to look at it and determine what I am going to do about it.

From a Quality Assurance (QA) standpoint, if you are going to streamline a process for efficency and increased quality (cost wise readiness), then it's got to start and be accepted by all members of the process. If HL is going to build a trailer, and they do build a nice unit

There is no additional cost associated with installing the wiring into a preplanned correct location or area that would allow for a neater and more professional installation. The technician is already in there doing the work, so what additional cost is associated with just putting in the right way for the first and only time? NONE. This is not a cost factor, it's a fact of not having a process in place that would foster a better install. It's been overlooked and accepted as "This is the way we have always done it" attitude that will keep them installing this way. This can change and I'm sure with the brand manager looking at these forums, that changes will come that will eliminate the sloppy intallations in the future.

There was someone that said he was not going to mess with it because if "It's not broke...don't mess with it" was his response. Well...in retort to that statement...I don't want to be setting up in the middle of the moutains ready for a wonderful RV'ing experience with my family when something is broken from the trip up there and have to listen to my wife complain that it's broken and that I should have checked it. So prevention is the key to success.

The Pre-Delivery Inspection (PDI) should be thorough as it can be. Hook it all up and check it all out with the dealer right there. If they don't make time for you, then demand it. Experienced or not, it's their job to deliver a unit to you that you are happy with. I did not take the time that I wanted to because I was on a schedule to get back home at a certain time. I live four hours from my dealer, so I assumed the risk associated with what I would discover once I set it up. I can repair most anything so I'm not affraid to repair the RV.

Please understand that I don't defend sloppy work, but at the time same time, if it's not part of the process to install it in a way that is neat and professional looking, then it won't change. Our input and feedback to HL is what is going to change the future RV's for the next potential HL owner.

I am enjoying my Big Country and look forward to many years of use out of my RV.

My two cents....

Scott

2009 Big Country 3490 RB

2005 Ford F-350 Lariet 6.0L Powerstroke DRW Crewcab

B

bwwalczak

Guest

Thank you for your post sdgrossman1994. Heartland is in a constant struggle to be better, every day, week, month, and year.

I would love to find out where you purchased your 3490RB. This model went out of production in 2008. We have had substantial improvements in the last two years.

Please feel free to let me know via email: bryanw@heartlandrvs.com

I would love to find out where you purchased your 3490RB. This model went out of production in 2008. We have had substantial improvements in the last two years.

Please feel free to let me know via email: bryanw@heartlandrvs.com

wyleyrabbit

Well-known member

Having "reasonably" neat and tidy wiring will cut down on problems and is better. It just is. I'm not suggesting that the wiring should be so good as to be ready to be on display with plexiglass panels in the basement wall and mood lighting in the wiring/plumbing compartments. Although that would be a cool mod, don't you think?

That said, the spaghetti is beyond ridiculous. Seriously? We've got a mix of 12V and 120V wiring completely mixed in with plumbing, and the plumbing has cheap plastic connections that tend to leak. Water and electricity are not a good mix!

I, for one, don't believe having the wiring and plumbing planned out logically before hand, and organized would add much to the price. I find it hard to believe that any actual plumbers or electricians would ever do the kind of work that we see in our very expensive trailers. Are there no minimum code standards required for RVs? Perhaps those of you that think having the job done properly by qualified people would increase the price because then Heartland would have to actually hire and/or train people to do the job properly. Maybe the trailer should cost a few hundred dollars more, if that's what it would take to have qualified people doing these critical jobs.

My dad is a professional electrician and there is no way he would ever do or accept such chaos. This rats nest would never pass inspection by any permit inspector in this part of the developed world, so why is this okay? Cars and trucks are not wired like this, neither are houses. I haven't ever owned a boat, but I find it hard to believe that they'd be like this either. RVs should be required to meed some reasonable standards.

Yes I feel strongly about this embarrassment behind the walls. The people involved need to hang their heads in shame and take some pride in their work and do the job properly. Plumbing needs to be well organized and use brass connections, not plastic that is bound to leak. Electrical needs to meet some level of minimum code and quality, and should be organized properly. This chaos could cause a fire and possibly take people's lives.

Chris

That said, the spaghetti is beyond ridiculous. Seriously? We've got a mix of 12V and 120V wiring completely mixed in with plumbing, and the plumbing has cheap plastic connections that tend to leak. Water and electricity are not a good mix!

I, for one, don't believe having the wiring and plumbing planned out logically before hand, and organized would add much to the price. I find it hard to believe that any actual plumbers or electricians would ever do the kind of work that we see in our very expensive trailers. Are there no minimum code standards required for RVs? Perhaps those of you that think having the job done properly by qualified people would increase the price because then Heartland would have to actually hire and/or train people to do the job properly. Maybe the trailer should cost a few hundred dollars more, if that's what it would take to have qualified people doing these critical jobs.

My dad is a professional electrician and there is no way he would ever do or accept such chaos. This rats nest would never pass inspection by any permit inspector in this part of the developed world, so why is this okay? Cars and trucks are not wired like this, neither are houses. I haven't ever owned a boat, but I find it hard to believe that they'd be like this either. RVs should be required to meed some reasonable standards.

Yes I feel strongly about this embarrassment behind the walls. The people involved need to hang their heads in shame and take some pride in their work and do the job properly. Plumbing needs to be well organized and use brass connections, not plastic that is bound to leak. Electrical needs to meet some level of minimum code and quality, and should be organized properly. This chaos could cause a fire and possibly take people's lives.

Chris

Similar threads

- Replies

- 2

- Views

- 4K

- Replies

- 1

- Views

- 1K

- Replies

- 3

- Views

- 2K